Fighting 99th Forum

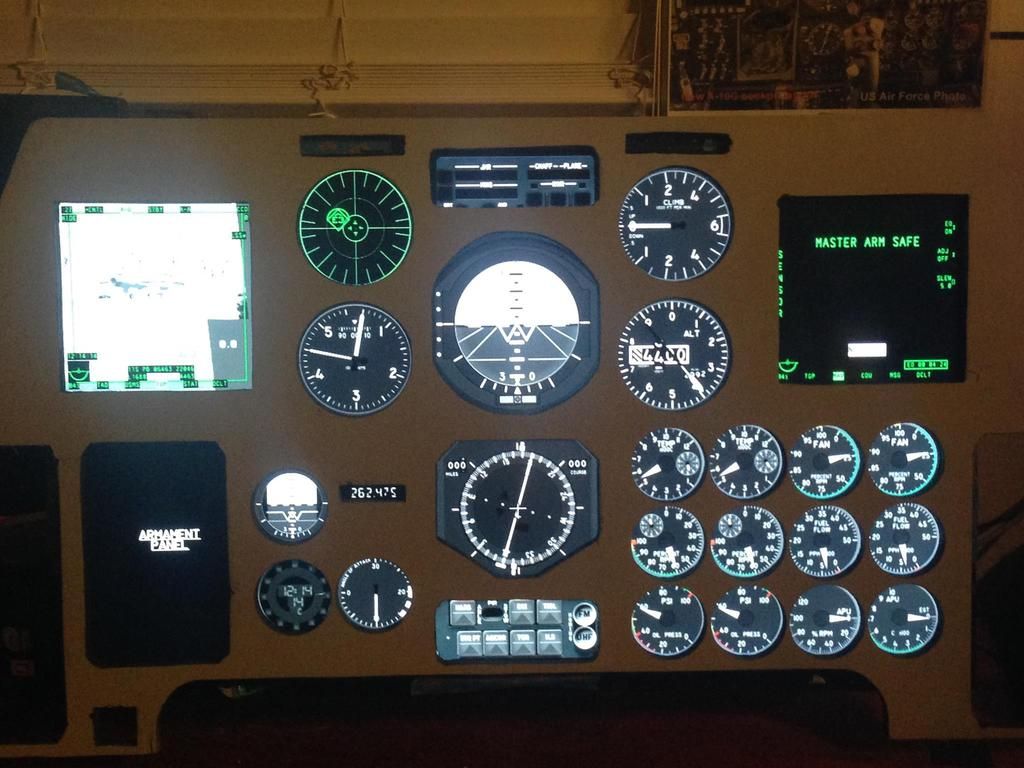

My Home Built Hogpit....

www.facebook.com/casey.welch.1428/media_...635029344&type=3

You don't have to have facebook to look at the photos, The album is open to the public.

Vid: www.facebook.com/casey.welch.1428/videos/860008694096957/

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

Sorry, this content isn't available right now

The link you followed may have expired, or the page may only be visible to an audience you're not in.

Go back to the previous page · Go to News Feed · Visit our Help CentePlease Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

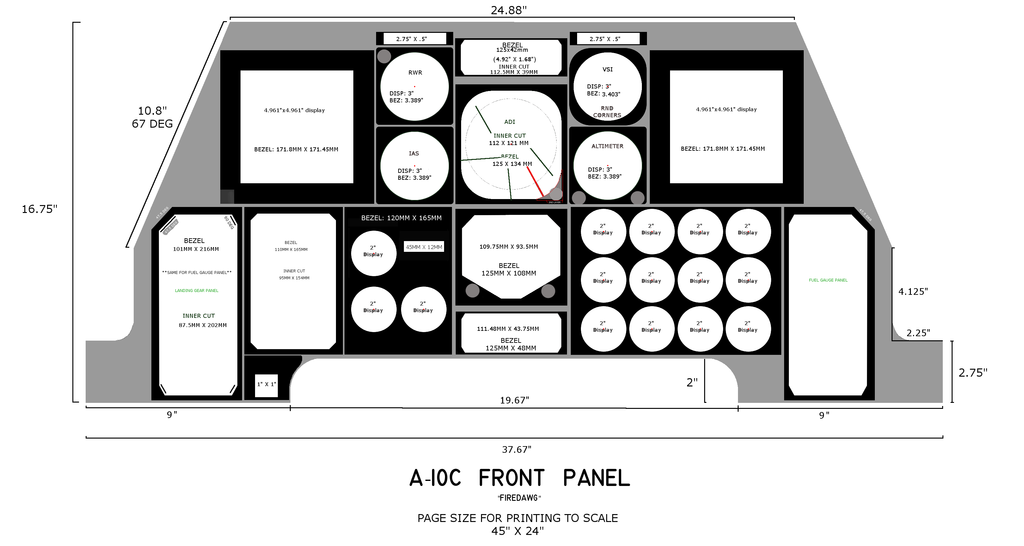

What material and thickness did you use for the faceplate? I have both acrylic and lexan sheets to experiment with. Did you use a CNC to cut? I have access to a mill, but that won't be as accurate.

Please Log in or Create an account to join the conversation.

I recommend using this for the faceplate www.rowmark.com/laser/LaserMAX/lasermax.asp.

This is engravable plastic so the engrave depth is always the same which allows you to be as accurate as possible.

You can use this, www.inventables.com/technologies/31-ligh...-white-acrylic-sheet

but you have to paint a coat of grey, then black, then engrave, then clear(matte) coat it. Takes more time and if you paint too thick or unevenly you wont have a uniform engrave depth across the panel.

The faceplate can be as thin/thick as you need, just needs to be durable.

i used a clear lexan polycarb piece for the "midplate" so that the rings of the switches have a gap and it provides a thick layer for LED placement. The clear polycarb with painted edges allows the light to remain trapped, and makes the illumination more distributed throughout the panel. The backplate(mounting plate) is also a piece of polycarb, thick enough to provide durability for the switches etc. It has to be durable enough to prevent cracking. Another option is aluminum back plate.

I use the Shapeoko 2 CNC, but the more updated machine is this www.inventables.com/technologies/x-carve.

Please Log in or Create an account to join the conversation.

and for knobs, get with me and ill mold some, still needing a few styles so I am constantly searching ebay for those.

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

Not the thrustmasters, I will be cutting my own to the actual dimensions of the real thing.

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.